Your Position: Home - Valves - How Do Proportional Hydraulic Valves Work and Improve System Control?

Proportional hydraulic valves play a vital role in modern hydraulic systems, providing precise control over fluid flow and pressure. They are crucial components for applications requiring exact system regulation, such as in construction machinery, robotics, and manufacturing systems. In this article, we’ll explore how proportional hydraulic valves work and how they can significantly improve system control, efficiency, and performance.

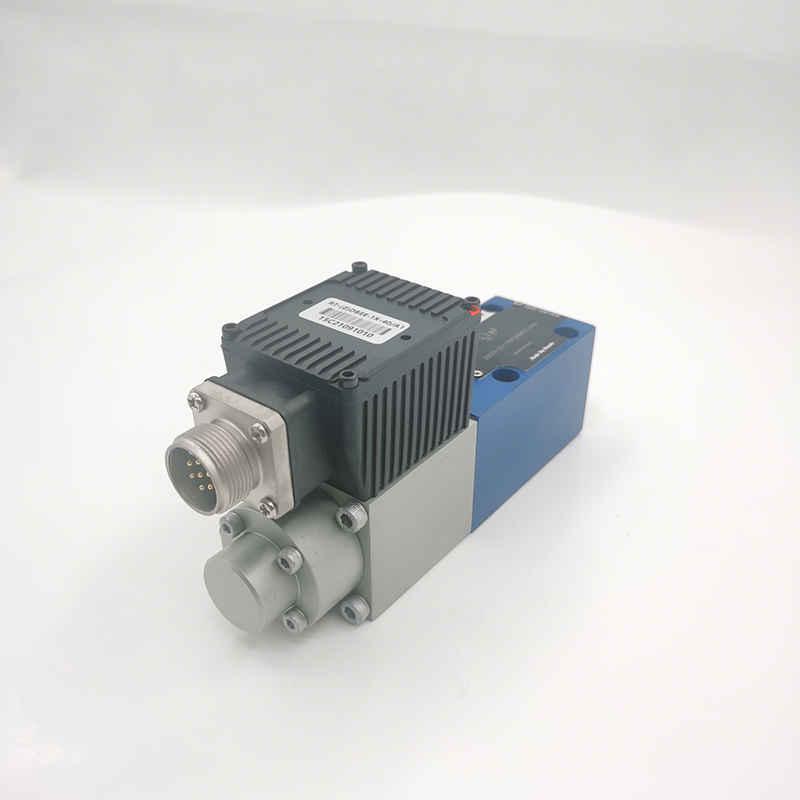

Proportional hydraulic valves are advanced devices used to control the flow and pressure of hydraulic fluids in a system. Unlike traditional on/off valves, proportional valves adjust the flow based on the input signal they receive, allowing for more precise control of the system. This level of control enables more efficient operation and helps prevent system overloads, improving both safety and performance.

Proportional valves operate based on an input signal, typically from an electronic controller. This signal can be either analog or digital, depending on the system’s requirements. The valve adjusts its position to correspond to the input signal, which dictates the level of hydraulic fluid flow.

When the valve receives the input signal, it opens or closes a valve seat proportionally. The valve’s movement is not binary (on/off) but varies based on the signal, providing precise control over the flow rate. The more the valve opens, the more fluid flows through, and the less it opens, the less fluid flows.

Along with controlling flow, proportional hydraulic valves also help maintain the system’s pressure. By adjusting the flow of fluid to specific parts of the system, these valves ensure that the system operates at optimal pressure, preventing over-pressurization or under-pressurization, which can damage components or reduce efficiency.

Many proportional hydraulic valves include a feedback mechanism to monitor system performance. This feedback ensures that the valve adjusts continuously to maintain the correct flow and pressure. Sensors detect changes in the system and send data back to the controller, which fine-tunes the valve’s position for constant, reliable performance.

One of the primary benefits of proportional hydraulic valves is their ability to provide precise control over fluid flow and pressure. This precision is crucial in applications like robotics, where exact movements and positioning are required, and in manufacturing, where consistent machine operation leads to better product quality and fewer errors.

By adjusting fluid flow according to real-time needs, proportional valves optimize the hydraulic system’s energy usage. This reduces unnecessary power consumption and lowers operating costs while ensuring that the system performs at its peak. The result is more efficient machinery and less wear and tear on components, ultimately extending the life of the equipment.

In many hydraulic systems, maintaining the correct pressure is vital for safety. Proportional hydraulic valves help prevent over-pressurization by regulating fluid flow, which can otherwise cause system failure or even dangerous accidents. Their feedback control systems ensure that the pressure remains stable, even during fluctuations in demand.

Proportional valves also enhance the responsiveness of hydraulic systems. The quick adjustments they make in real time ensure that the system reacts promptly to changes in load, speed, or direction. This is especially beneficial in applications such as construction machinery or industrial robots, where flexibility and rapid adjustments are essential for performance.

Hydraulic proportional flow control valves are indispensable for modern hydraulic systems. By providing precise control over fluid flow and pressure, they significantly improve system efficiency, safety, and performance. Their ability to offer real-time adjustments based on input signals makes them ideal for high-precision applications in industries such as manufacturing, robotics, and construction. If you have any questions or would like to learn more about how proportional hydraulic valves can benefit your system, feel free to leave a comment or reach out!

6

0

0

Comments

All Comments (0)