Your Position: Home - Machinery - How Does Induction Heating System for Forging Work?

Induction heating in the forging industry is a revolutionary technology that has transformed traditional manufacturing processes. As a web content editor seeking to enhance reader engagement and drive website traffic, understanding the intricacies of how induction heating systems work for forging is crucial. In this article, we will explore the principles, components, and applications of induction heating, answering key questions to satisfy the readers' search intent.

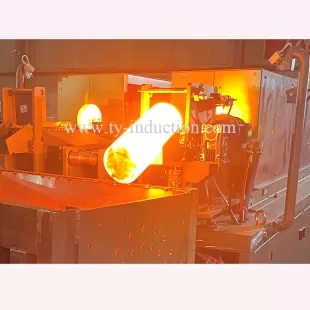

At its core, induction heating is a method of generating heat within a conductive material through the use of electromagnetic fields. In the context of forging, this process is instrumental in achieving precise and controlled temperatures for shaping metal.

The induction heating system comprises three main components: the power supply unit, induction coil, and workpiece. The power supply unit generates high-frequency alternating current, which passes through the induction coil, creating a powerful magnetic field. This magnetic field induces eddy currents within the workpiece, causing it to heat up.

In forging, the induction heating system is employed to heat metals to the desired temperature for shaping. The electromagnetic induction process ensures rapid and uniform heating, allowing for greater control over the forging process. As the metal reaches the required temperature, it becomes malleable, facilitating the forging of intricate shapes and designs.

The efficiency and precision of induction heating make it highly advantageous in forging applications. Unlike traditional heating methods, induction heating allows for quick and targeted temperature adjustments, reducing energy consumption and enhancing overall efficiency. This makes it a preferred choice for industries where precision and speed are paramount.

Suggested reading:Induction heating finds wide-ranging applications in the forging industry, particularly in the automotive, aerospace, and general manufacturing sectors. The ability to precisely control temperatures makes it suitable for various metalworking applications, from shaping components for automobiles to producing intricate parts for aerospace technologies.

Addressing misconceptions is crucial to understanding the true benefits of induction heating. Some may believe it's a complex or costly process, but the reality is that technological advancements have made induction heating more accessible and cost-effective than ever before. Debunking these myths helps readers appreciate the advantages of adopting this technology.

Comparing induction heating to traditional methods highlights its superiority in forging applications. Unlike traditional furnaces or ovens, induction heating is faster, more energy-efficient, and allows for better temperature control. This section provides a detailed comparison, showcasing why industries are increasingly adopting induction heating.

While the benefits of induction heating are evident, businesses considering its adoption must weigh certain factors. Initial investment costs, training requirements, and long-term benefits are crucial considerations. This section offers insights to help businesses make informed decisions when implementing induction heating systems.

No technology is without its challenges. This section addresses common issues in induction heating, such as heat distribution and system maintenance, and explores innovative solutions that have been developed to overcome these challenges.

Looking ahead, the future of induction heating holds exciting possibilities. Emerging technologies, including advancements in materials and control systems, are poised to further enhance the efficiency and capabilities of induction heating in the forging industry.

In conclusion, the induction heating system for forging is a cutting-edge technology that has reshaped the landscape of metalworking. Its efficiency, precision, and versatility make it a valuable asset for industries aiming to stay at the forefront of innovation. As businesses continue to embrace induction heating, the forging process is set to become even more streamlined and environmentally friendly.

335

0

0

Comments

All Comments (0)

Related Articles

How to Choose a Portable Induction Heating Machine

ortable induction heating machines have become essential tools in various industries, from metalworking to construction and beyond. Their ability to quickly and efficiently heat metals for various applications makes them valuable assets.

By Hou

326

0

0

What is a concrete extruder?

What is a concrete extruder? A concrete extruder is a specialized construction machine designed for the precise and efficient extrusion of concrete. This innovative equipment plays a pivotal role in modern construction projects, offering numerous advantages in terms of speed, precision, and cost-effectiveness.

By Liang

305

0

0

What is the DTH method of drilling?

Down-the-Hole (DTH) drilling is a powerful and efficient method used in the mining, construction, and geotechnical industries for drilling boreholes into the Earth's subsurface. This technique involves a pneumatic or hydraulic hammer attached directly to the bottom of the drill string

By Hou

300

0

0

What are the different types of RC drilling rig?

Reverse Circulation (RC) drilling rigs play a pivotal role in mineral exploration and other drilling applications, providing a reliable method for collecting rock samples. These rigs are versatile and come in various types, each designed to address specific drilling challenges and geological conditions.

By Hou

325

0

0

What is a adjustable spacer block?

An adjustable spacer block is a specialized component designed to provide a means of precise adjustment or spacing between two objects or components in various applications. These blocks are adjustable to accommodate specific requirements, allowing for fine-tuning and customization.

By Hou

318

0

0

5 facts for safe use of aerial lifts

Aerial lifts are invaluable tools in various industries, providing access to elevated workspaces. However, their use comes with inherent risks that demand careful attention to safety protocols. Whether you're operating a scissor lift, boom lift, or any other type of aerial platform, understanding and adhering to safety guidelines is paramount.

By Hou

304

0

0

What is Biomass Briquetting Machine?

A biomass briquetting machine is a specialized piece of equipment designed to convert biomass materials into a compact, solid, and energy-dense form known as biomass briquettes. These machines play a crucial role in addressing environmental concerns related to waste disposal and fossil fuel usage.

By Hou

307

0

0

Why Choose Fully Automatic Flour Mill Plant?

In the realm of flour milling, the choice of equipment plays a pivotal role in determining the efficiency and quality of the end product. Among the various options available, opting for a Fully Automatic Flour Mill Plant emerges as a strategic decision that brings forth a multitude of benefits.

By May

320

0

0