Your Position: Home - Metal & Metallurgy Machinery - Does Metal Lath Rust?

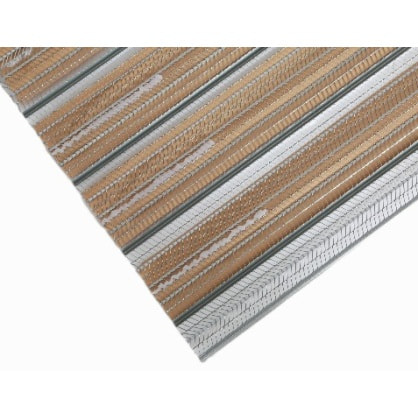

Metal lath, commonly used in construction, is a mesh or sheet made from expanded metal or wire. It provides a supportive base for applying plaster, stucco, or other finishing materials. Metal lath is known for its durability and strength, making it a popular choice for both interior and exterior applications. However, a common concern among users is whether metal lath rusts and how to mitigate this issue.

Metal lath is typically made from steel, which is an alloy of iron and carbon. Steel's properties make it an excellent material for construction due to its strength, flexibility, and availability. However, because steel contains iron, it is susceptible to rust when exposed to moisture and oxygen over time. Rust, or iron oxide, forms when iron reacts with oxygen in the presence of water or air moisture, leading to the corrosion of the material.

Several factors can influence the rate at which metal lath rusts:

Exposure to Moisture: Metal lath used in exterior applications or in areas with high humidity is more prone to rusting due to increased exposure to moisture.

Environmental Conditions: Coastal areas with salty air can accelerate the rusting process due to the presence of salt, which enhances the conductivity of water, leading to faster oxidation.

Protective Coatings: The presence or absence of protective coatings, such as galvanization or paint, significantly affects the metal's susceptibility to rust.

Installation Techniques: Proper installation techniques, including the use of appropriate fasteners and ensuring the lath is not in direct contact with the ground, can help reduce the risk of rusting.

To prevent rusting, several methods and treatments can be applied to metal lath:

Galvanization: One of the most effective methods is galvanization, where the steel is coated with a layer of zinc. Zinc acts as a barrier, preventing moisture and oxygen from reaching the steel surface. Additionally, zinc is more reactive than iron, so it corrodes first, offering sacrificial protection to the underlying metal.

Protective Coatings: Applying protective coatings such as paint, epoxy, or powder coatings can shield the metal lath from moisture. These coatings create a physical barrier that prevents water and oxygen from coming into contact with the metal surface.

Proper Installation: Ensuring that metal lath is properly installed can help reduce its exposure to elements that cause rust. For example, using non-corrosive fasteners and avoiding direct contact with the ground can help prolong the life of the lath.

Regular Maintenance: Inspecting and maintaining metal lath installations regularly can help identify and address early signs of rust before they cause significant damage. This includes cleaning the lath to remove dirt and debris that can hold moisture.

Suggested reading:Galvanized metal lath is widely used in construction due to its enhanced resistance to rust. The galvanization process involves dipping the steel in molten zinc, forming a robust, corrosion-resistant coating. This makes galvanized metal lath suitable for various applications, especially in environments prone to moisture and humidity.

Longevity: Galvanized metal lath has a longer lifespan compared to non-galvanized lath, as the zinc coating protects it from rusting.

Cost-Effective: Although initially more expensive, galvanized metal lath reduces long-term maintenance and replacement costs, making it a cost-effective choice.

Versatility: Suitable for both interior and exterior applications, galvanized metal lath provides reliable support for plaster and stucco finishes in various environments.

Reduced Maintenance: The protective zinc coating minimizes the need for frequent inspections and repairs, ensuring the structure remains intact and aesthetically pleasing.

Metal lath, while inherently susceptible to rust due to its steel composition, can be effectively protected through galvanization and other preventive measures. Understanding the factors that contribute to rusting and implementing appropriate protective strategies can significantly extend the lifespan of metal lath in construction applications. Galvanized metal lath stands out as a preferred choice, offering durability, cost-effectiveness, and versatility. By choosing the right type of metal lath and ensuring proper installation and maintenance, builders and homeowners can enjoy the benefits of this essential construction material without the worry of rust-related issues.

207

0

0

Comments

All Comments (0)

Related Articles

How Does an Automated Soybean Oil Extraction Machine Work?

Automated soybean oil extraction machines have revolutionized the way oil is processed in the agricultural sector.

By Fayella

98

0

0

2024 Trends: Automatic Heating Avocado Oil Press Machine

As we move into 2024, the demand for healthy cooking oils continues to surge, with avocado oil leading the charge.

By becky

92

0

0

Two Shaft Shredder vs. Single Shaft: Which Is Better?

When it comes to waste management and recycling, choosing the right shredder can significantly impact efficiency and effectiveness.

By Geoff

110

0

0

Affordable Shea Butter & Tea Seed Oil Extractors

When it comes to natural beauty products, shea butter and tea seed oil stand out for their remarkable benefits.

By Harry

97

0

0

Unlocking Efficiency: Two-Shaft Shredder Production Secrets

Understanding the Two-Shaft ShredderThe two-shaft shredder is a vital piece of equipment in various industrial applications.

By Geym

104

0

0

4 Tips to Select the Right Two-Shaft Shredder for Your Needs

Choosing the right two-shaft shredder for your business can significantly impact efficiency and productivity.

By Molly

115

0

0

Top Trends for Industrial Electric Steam Generators 2024

### Article: .

By CC

95

0

0

How Do Industrial Electric Steam Generators Work?

Industrial electric steam generators are essential tools in various industries, providing efficient and reliable steam for numerous applications.

By wenzhang1

94

0

0