Your Position: Home - Other Machinery & Industry Equipment - What is automatic Labelling machine?

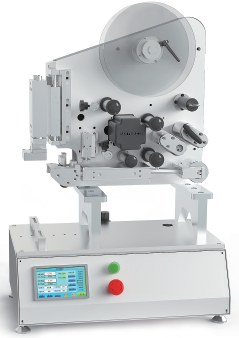

An automatic labeling machine is a sophisticated piece of equipment designed to apply labels to products or packaging in an efficient and precise manner. Also known as label applicators or labelers, these machines automate the labeling process, replacing manual efforts and ensuring consistency and accuracy in labeling applications across various industries.

Key Features and Components:

Conveyor System: Automatic labeling machines often incorporate a conveyor system that moves products through the labeling process seamlessly. This ensures a continuous and efficient labeling workflow.

Label Dispenser: The label dispenser is a key component responsible for feeding and releasing labels onto the products. It may use various mechanisms, such as peel-and-apply or tamp-blow, depending on the specific design of the labeling machine.

Application Head: The application head is the mechanism responsible for accurately placing the label on the product. This can involve methods like pressure-sensitive application, where the label adheres upon contact, or heat and glue application for certain types of labels.

Label Roll Holder: Labeling machines are equipped with a label roll holder or reel stand to accommodate and dispense label rolls. This ensures a continuous supply of labels during the labeling process.

Control System: Modern automatic labeling machines come with sophisticated control systems that allow operators to set parameters such as label size, placement, and speed. Some machines may also have touch-screen interfaces for easy programming and monitoring.

Types of Automatic Labeling Machines:

Wrap-around Labelers: Ideal for cylindrical or round products, these machines apply labels that wrap around the entire circumference of the item.

Top and Bottom Labelers: Designed to apply labels on both the top and bottom surfaces of flat or rectangular products, ensuring comprehensive product information.

Suggested reading:Front and Back Labelers: Suitable for products that require labeling on both the front and back surfaces, providing visibility from different angles.

High-Speed Labelers: Engineered for industries with high-volume production, these machines are designed to label products swiftly and accurately, contributing to increased efficiency.

Benefits of Automatic Labeling Machines:

Increased Efficiency: Automation significantly speeds up the labeling process, leading to higher production rates and reduced labor costs.

Accuracy and Consistency: Automatic labelers ensure precise label placement and consistency across all products, reducing the risk of labeling errors.

Versatility: These machines can handle a variety of label types, sizes, and materials, making them adaptable to diverse product labeling requirements.

Reduced Waste: Advanced control systems enable precise label positioning, minimizing the likelihood of wasted labels and reducing material costs.

Compliance and Traceability: Automatic labeling machines contribute to compliance with industry regulations by providing accurate and traceable labeling information on products.

In summary, automatic labeling machines play a crucial role in industrial and manufacturing settings by automating the labeling process. Their efficiency, accuracy, and versatility make them invaluable tools for businesses seeking to enhance productivity and maintain high standards of product labeling.Learn more

197

0

0

Comments

All Comments (0)

Related Articles

Can a Concrete Column Machine Change the Way You Build?

A Concrete Column Machine is a revolutionary construction tool that produces precise, high-quality concrete columns efficiently. Learn how this technology can transform your building projects in this article.

By Evelyn

294

0

0

How Do I Know What Size Hydraulic Pump I Need?

A hydraulic pump is a mechanical device that converts mechanical power into hydraulic energy, crucial in various industries, such as manufacturing, construction, and automotive.

By Evelyn

383

0

0

Advantages and Applications of CNC Gang Tool Lathes

A CNC Gang Tool Lathe, often referred to as a CNC Swiss Lathe, is a specialized machine used for precision turning and milling operations. This advanced technology allows for multiple tool operations, enabling the production of intricate components with high accuracy.

By May

311

0

0

5 Key Considerations When Selecting a Robotic Soldering System

When picking a robotic or automated soldering robot, it is important to look at the following factors:

By Hou

292

0

0

How Does a Sand Making Machine Work?

Unlocking the secrets of construction and manufacturing, the Sand Making Machine transforms raw materials into versatile sand, shaping industries with precision and enhancing the foundations of modern infrastructure.

By Evelyn

312

0

0

What is the Principle of Waste Air Separator?

Unlock energy efficiency with waste air separators. These devices optimize system performance by removing excess air, saving costs, extending equipment lifespan, and promoting environmental sustainability.

By Evelyn

310

0

0

What are the Advantages of Using Induction Heating for Forging?

In the dynamic realm of metalworking, efficiency, precision, and cost-effectiveness are paramount. Induction heating stands out as a revolutionary technology, redefining the landscape of forging processes. As industry leaders, we understand the pivotal advantages that induction heating brings to the table, making it an indispensable tool for modern forging operations.

By May

242

0

0

Unlocking the Potential: A Comprehensive Evaluation of Swing Motors

Swing motors, crucial components in various machinery, govern rotational movements. This introduction explores the significance of assessing these motors for optimal performance, safety, and longevity in diverse applications.

By Evelyn

297

0

0